INDUSTRIAL EPOXY FLOOR

When it comes to industrial spaces, the demands on your flooring are as tough as they come. From heavy equipment to chemical spills, your floors need to withstand just about anything. That’s where industrial epoxy floors shine (figuratively and literally). Whether you’re managing a warehouse, automotive shop, or distribution center, our industrial epoxy flooring solutions provide the strength, durability, and low maintenance you need to keep things running smoothly. Not to mention — they look amazing.

Key Benefits

Here’s why industrial epoxy is the go-to solution:

- Heavy-Duty Durability: Industrial floors take a beating. Our epoxy floors are engineered to handle constant foot traffic, heavy machinery, and impacts without cracking or showing wear.

- Chemical Resistance: Industrial settings often involve exposure to harsh chemicals. Epoxy floors are non-porous, preventing damage from chemical spills, making them ideal for environments like manufacturing plants and food processing facilities.

- Safety First: Slips and falls are a big concern in industrial facilities. Our epoxy coatings can be customized with anti-slip finishes and safety zones to help reduce accidents and improve overall safety.

- Long-Lasting: Whatever you’re doing with those floors, they’ll be around for a long time.

Ideal for a Range of Industrial Spaces

No matter what kind of industrial facility you operate, epoxy flooring offers a reliable, long-lasting solution. Common applications include:

- Warehouses and Distribution Centers: With the constant movement of forklifts and heavy loads, epoxy floors provide a durable surface that can handle the stress.

- Manufacturing Plants: These floors are built to endure heavy machinery, assembly lines, and chemical exposure, making them perfect for high-demand environments.

- Pharmaceutical Laboratories: Clean, smooth, and easy to sanitize, epoxy flooring is the preferred option for laboratories where cleanliness is critical.

- Food and Beverage Processing Facilities: Epoxy floors are highly resistant to moisture, spills, and frequent washdowns, making them ideal for maintaining sanitation in areas that require strict hygiene standards.

- Automotive Repair Shops and Service Bays: Constant exposure to oil, grease, and chemicals requires a floor that can handle spills and abrasions. Epoxy flooring offers a slip-resistant surface that withstands heavy vehicle traffic and frequent cleaning.

- Cold Storage Facilities: Epoxy floors are resistant to extreme temperatures and can handle the constant shifts in temperature found in cold storage and freezer rooms without cracking or losing integrity.

- Aircraft Hangars: In environments where heavy aircraft and equipment are moved regularly, epoxy floors provide the strength needed to withstand heavy loads while resisting chemicals like jet fuel and hydraulic fluids.

This doesn’t list everything, but we hope it gives you a good idea of just how versatile epoxy floor coatings can be.

Our Installation Process

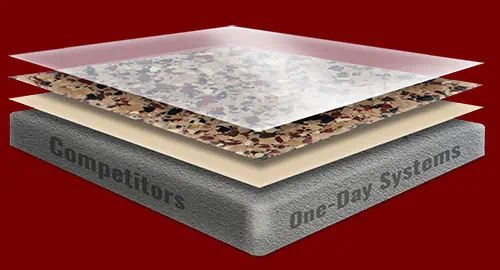

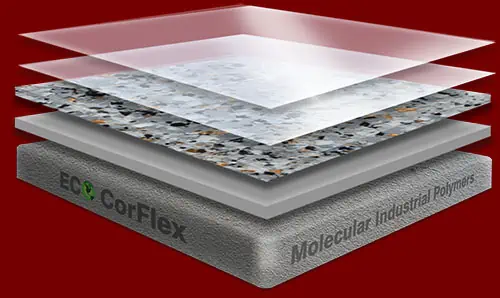

Our industrial epoxy floors are installed using a meticulous, multi-layer process designed for maximum durability and performance in demanding environments:

- Surface Preparation: The success of any epoxy flooring installation starts with proper surface preparation. We begin by mechanically grinding the existing concrete surface, removing any imperfections, old coatings, or debris that could interfere with adhesion. This process not only smooths out the surface but also creates the necessary texture (profile) for the epoxy to bond effectively. A properly prepared surface is essential to ensuring the longevity of the epoxy floor, preventing peeling, bubbling, or early failure.

- Moisture Barrier: Once the surface is prepped, we apply a specialized moisture-managing epoxy primer. Industrial environments often deal with varying moisture levels, which can compromise the adhesion of the epoxy if not addressed. Our primer acts as a sealant, creating a barrier that prevents moisture from seeping up through the concrete and disrupting the bond between the floor and the epoxy. This step is crucial in environments prone to spills, humidity, or temperature fluctuations, as it ensures long-term adhesion and prevents issues like blistering and delamination.

- Heavy-Duty Topcoat: To finish the process, we apply a robust polyaspartic or epoxy topcoat tailored to the specific needs of your facility. This topcoat serves as the first line of defense against the wear and tear of industrial use, providing resistance to impacts, abrasions, chemicals, and UV exposure. Whether dealing with forklift traffic, heavy machinery, or corrosive substances, this final layer is engineered to protect the floor for years to come. Additionally, it can be customized with anti-slip finishes, safety markings, or color zones to enhance safety and functionality within the workspace.

This multi-step approach ensures that your epoxy floor isn’t just aesthetically pleasing but built to withstand the toughest conditions in industrial settings.

Contact Us for Industrial Epoxy Floor Installation

Ready to upgrade your industrial facility with epoxy flooring that works as hard as you do? Our team at GarageFloorCoating.com provides professional industrial epoxy floor installation throughout the country. Reach out today for a quote!

Over 25 years experience in epoxy flooring applications

Do it Right the First Time with Our Coating Systems

Seeking out other bids?

% SATISFACTION

Officially tracked and measured.

LOCATIONS

Located throughout the United States.

MILLION SQ FT

Coated coast to coast.