“One-Day Polyurea” Coating Systems: Speed and Quality Don’t Equate

An increase in the popularity of concrete coatings has led to a boom in the number of new companies in the market, eager to meet this demand. The trend towards “1-day polyurea” or “1-day polyaspartic” coating systems is driven by customers’ preference for quick, one day installations. To accomplish these speedy installs, contractors employ rapid-curing liquid coatings known as polyureas or polyaspartics. However, in an article we posted back in August 2020, titled “Polyurea-Polyaspartic One-Day Systems: Do They Work‘, warns that speed and quality simply don’t equate when it comes to concrete coatings. How do we know? Because we have extensive experience installing concrete coatings (since 1996) – we’ve installed thousands – and we’ve seen the results of (and have had to repair) many “1-day polyurea-polyaspartic” installs.

What Differentiates a Polyurea from a Polyaspartic?

Contractors who promise single-day concrete coating installations use either “polyureas” or “polyaspartics”, applying them both as a primer coat (direct-to-concrete) and later as a clear topcoat…this turns out to be the problem…but read on. As part of their sales pitch, these same contractors will highlight how technologically advanced these products are—emphasizing the quick-curing nature, along with extreme UV protection and resistance to stains and impacts—all true claims indeed. Conveniently though, they also debase other coating types, like epoxies, that should be used in quality coating systems.

But let’s first delve into understanding what actually differentiates a polyurea from a polyaspartic. These two coatings have distinct chemical compositions, but essentially, a polyaspartic is simply a more user-friendly version of a polyurea. It’s in fact, an aliphatic polyurea, formulated to slow down the curing time (“pure” polyureas can cure in seconds) to permit easier application. That is, the slowed down cure rate of a polyaspartic allows the applicator to apply their concrete coatings using a roller or squeegee (there’s no need for specialized equipment). Keep in mind, however, that even a “slowed-down” polyaspartic cures quite quickly – certainly quicker than an epoxy.

The Drawback of Using a Polyurea-Polyaspartic as the Primer Coat

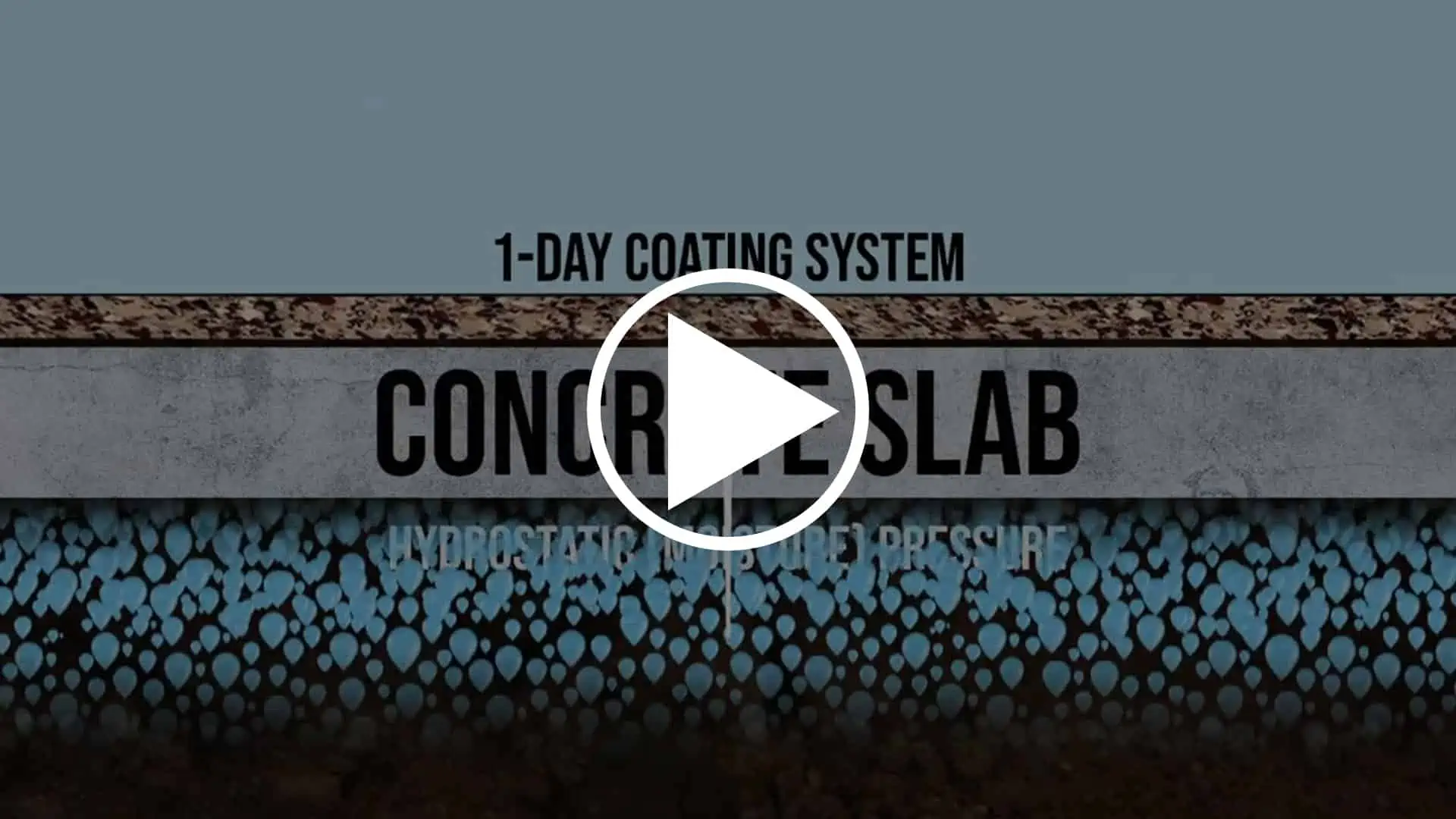

However, there’s a twist! Polyurea-polyaspartics aren’t suitable (and not spec’d) for direct-to-concrete application – especially concrete with medium to high moisture levels. This is due to the inherent characteristics of a polyaspartic’s curing process (or aliphatic polyurea…whatever you decide to call it). These coatings can’t be applied thickly; they’re only designed for thin-to-moderate film builds. Over time, as water wicks up through the porous concrete, in a process called moisture vapor transmission, a hydrostatic pressure builds. Under high hydrostatic pressures, the wafer-thin polyurea-polyaspartic coatings start to degrade…they delaminate or peel. And this explains why “1-day” contractors always include a warranty exclusion against “moisture-related issues” including “high hydrostatic pressures”!

Despite their seemingly long guarantee – many “1-day” contractors offer lifetime or 15 to 20 year guarantees – the warranty exclusion to “moisture-related issues”, and in some cases hot-tire transfer, can be invoked if and when the coating starts to peel (or stain). Since peeling and staining are the number one reasons for coating system failures, this is a significant drawback! In fact, the warranty isn’t worth the paper it’s written on.

Considering a “1-day polyurea” coating system? Ask yourself this:

If your “1-day” installer is so confident in their products and coating systems, why won’t they fully warrant against moisture-related issues and staining?

The Solution – Use an Epoxy as the Primer Coat

Epoxies cure by way of an exothermic reaction (heat is created). Unlike a polyurea-polyaspartic, these products cure in such a manner that the greater the mass – that is, the thicker it is – the faster it cures. This property allows epoxies to be applied very thickly. In fact, epoxies are called “high-build” coatings. And this thick epoxy primer coat is far more effective at withstanding high hydrostatic pressures than a polyurea-polyaspartic. Honest contractors (and Architects) would never recommend or apply a polyurea-polyaspartic direct to concrete.

But, despite being excellent primers, epoxies have their limitations too! They have low resistance to UV rays (sunlight) and tend to amber or fade over time. They also do not have the same extreme chemical resistance as is offered by a polyurea-polyaspartic. Hence, these characteristics make epoxies poor topcoats!

But what if we created a coating system that combined the best properties of both coating product types? That is, what is we used an epoxy as the primer coat and a polyurea-polyaspartic as the clear top coat?

This is What We Do: It’s How Quality Coating Systems are Built

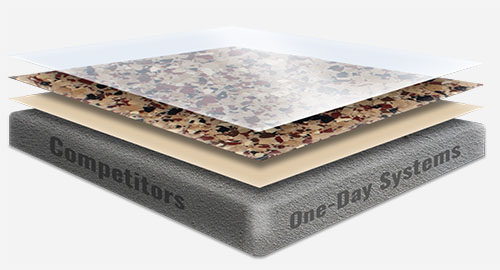

Sub-standard, “1-day” coating systems consist of 3 layers: (a) a wafer-thin polyurea-polyaspartic primer coat (layer 1), (b) a full broadcast of thermoplastic flakes (layer 2), and (c) a thin clear polyaspartic topcoat (layer 3). As discussed above, this quickly (and thinly) applied concrete coating is susceptible to delamination under medium to high moisture conditions. Why would contractors install these coatings? Because they require less product and less labor…so they’re very profitable!

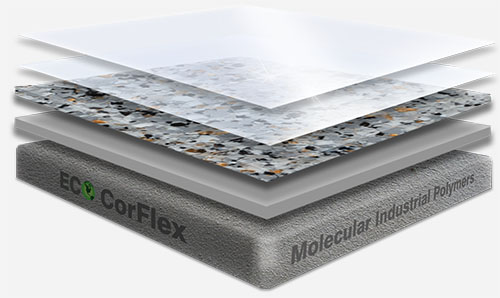

Conversely, our industrial-grade coating systems use the best properties of both epoxies and polyurea-polyaspartics to produce the thickest, highest-quality coating systems. Our coatings are 4-layers thick, including: (a) moisture-mitigating epoxy primer coat (layer 1), (b) a full broadcast of a thermoplastic & mica-mineral flake blend (layer 2), and (c) two separate coats of our clear, 100%-solids polyaspartic (layers 3 and 4). Our coatings are over 35 mils thick and are fully warranted against all moisture-related issues (unlike the “1-day” alternative).

But, because our coating system uses a slower-curing epoxy as the primer coat, our installations take 2 days, not 1. And now you know…that’s a good thing! Speed and quality don’t equate when it comes to coating system installations.

Above and Beyond

Our flooring solutions are simply above-and-beyond any “1-day” system out there.

We only use industrial-grade, 100%-solids liquid coatings. We prepare and then prime the concrete floor using our proprietary, moisture-mitigating epoxy primer (we’ll never use a polyurea-polyaspartic direct-to-concrete). We not only offer standard thermoplastic flake bends, we also offer more than 30 blends of our proprietary mica-infused flake blend (and blends that mimic polished concrete!). And all our full-flake garage floor coatings are topped by 2 layers – not just one – of our 100%-solids polyaspartic. We guarantee the most resilient concrete flooring and back it up with a full warranty against “moisture-related issues” and hot-tire transfer…no small print! “1-day” installers just can’t match our flooring!

We’re your expert installer of industrial-grade, concrete floor coatings. Call us today at (877)-324-2628 for your free estimate.

Ours

Theirs