The epoxy flooring industry is filled with specialized terminology that can be confusing for homeowners and businesses alike. Understanding these key terms can help you make informed decisions about your flooring options and ensure you choose the right products for your space. Below, we define some of the most commonly used words in the epoxy flooring industry.

Epoxy Flooring Industry Terms: Epoxy Coatings

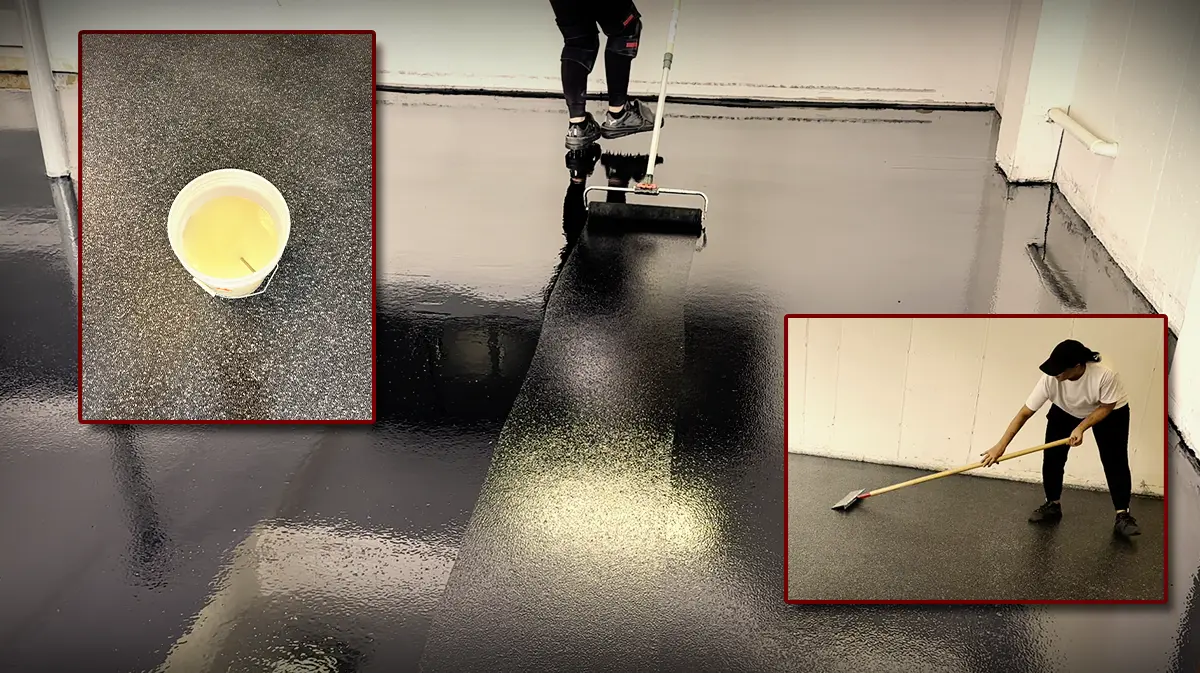

An epoxy coating is a two-part mixture of resin (Part A) and hardener (Part B) that forms a durable, high-gloss surface when applied to concrete floors. Epoxies are known for resistance to chemicals, wear, and moisture, making them a popular choice for both residential and commercial applications. Epoxy is particularly favored in garages, basements and commercial spaces as a moisture-mitigating primer coat. It’s slow cure rate enables it to deeply penetrate and bond with the concrete substrate, creating a moisture vapor barrier. However, epoxies tend to fade over time when exposed to sunlight. In this regard, they are best suited for interior applications (or should be covered with a full flake blend or color coat). Yet their ability to resist moisture vapor transmission and high hydrostatic pressure make them unmatched direct-to-concrete primer coats.

Epoxy Flooring Industry Terms: Polyaspartic Coatings

A polyaspartic (or polyurea) coating is a fast-cure coating, relative to an epoxy. Polyaspartic coatings can be applied in a wider range of temperatures and provide extreme UV and chemical resistance (they won’t yellow over time). Polyaspartics do have a downside. They can only be applied thinly (unlike “high-build” epoxies) and cure so quickly in the presence of moisture that they fail to properly penetrate the concrete substrate. That is, they are excellent clear top coats, but poor direct-to-concrete primer coats. Polyaspartics are often used as the top coat for garages, outdoor and commercial spaces, and spaces where a rapid return-to-service is essential.

Epoxy Flooring Industry Terms: Polyurethane Coatings

Polyurethane is another protective coating often used as a color coat over an epoxy primer. It provides excellent resistance to UV rays, chemicals, and scratches. However, polyurethanes can be odorous and susceptible to plasticizer migration (hot tire staining). As such, polyurethanes are best suited for outdoor applications, i.e., patios and walkways, and should never be used in a garage.

Flake Epoxy Floor System

A flake epoxy floor system is a type of decorative flooring where colored polyvinyl acetate (PVA thermoplastic) and/or mica mineral flakes are broadcast into the wet epoxy layer. These flakes not only add aesthetic appeal but also improve the texture of the floor, making it (somewhat) more slip-resistant. Flake epoxy floor systems are commonly used in garages, basements, and commercial spaces where both style and safety are essential.

Full Flake Epoxy Floor Coating

In a full fake epoxy floor coating system, the floor is completely covered with decorative flakes. This type of coating provides a thicker, more durable finish that improves hides imperfections in the concrete surface. Full flake epoxy floor coatings are particularly popular in high-traffic areas like garages, retail spaces, and showrooms. They are the thickest coatings and typically provide the longest warranties.

Mica

Mica is a naturally occurring mineral that can be added to epoxy flooring systems to provide added reflectivity and natural stone-like appearance. The reflective qualities of mica add depth and dimension to the floor, making it a popular choice for residential and commercial settings looking for a high-end, eye-catching finish.

Moisture Mitigation

Moisture mitigation refers to the process of addressing moisture vapor transmission (and the resulting hydrostatic pressure). Trapped moisture wicks its way up through porous concrete and creates a pressure that pushes upwards on an applied coating. Thin, poor-penetrating polyurea or polyaspartic primer coats are susceptible to delamination, blistering, or peeling over time. Conversely, a moisture-mitigating epoxy primer is the best choice for ensuring a strong bond with concrete, mitigating future moisture-related damage.

Garage Floor Coating

When people talk about a “garage floor coating,” they’re usually referring a system of layered epoxy and/or polyaspartic coatings. These thick coatings protect garage floors from moisture infiltration, automotive fluid spills, scratches, and heavy loads. They’re popular because they not only strengthen the floor but give it a customized look with various colors, textures, and finishes.

Concrete Floor Paint / Concrete Paint

Often casually referred to as “concrete paint,” this is a term people use when they mean epoxy or similar coatings. However, concrete paint is less durable than epoxy. It sits on the surface of the concrete rather than bonding with it, making it better suited for lighter-duty uses where appearance is more important than long-term protection.

Waterproofing Basements

Waterproofing a basement involves applying a moisture-resistant coating, such as moisture-mitigating or moisture-resistant epoxy, to prevent water from seeping through the concrete walls or floor. This not only protects the structural integrity of the basement but also prevents issues like mold growth, water damage and indoor air quality issues.

Metallic Epoxy Floor

A metallic epoxy floor is a decorative flooring option that incorporates metallic pigments into the epoxy resin, creating a three-dimensional, marbled effect. The unique, high-gloss finish of metallic epoxy floors makes them a popular choice for residential homes, showrooms, and high-end commercial spaces looking for a luxurious and modern aesthetic.

Conclusion

By understanding these common terms in the epoxy flooring industry, you can better navigate your options and choose the right flooring system for your needs. Whether you’re seeking durability, aesthetic appeal, or moisture protection, knowing these terms ensures you’re making informed decisions. For expert installation and guidance, always consult with a professional to assess your specific requirements.

About the Author

Share this Post