Combating 1-Day Systems

How do our coating systems differ?

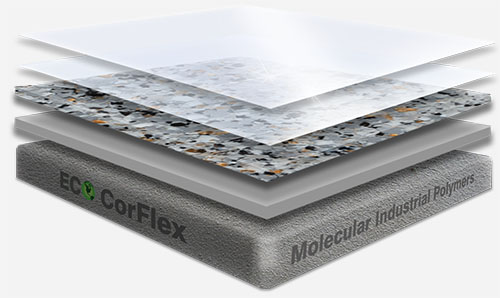

Ours

Our Coating System = 35+ mils thick

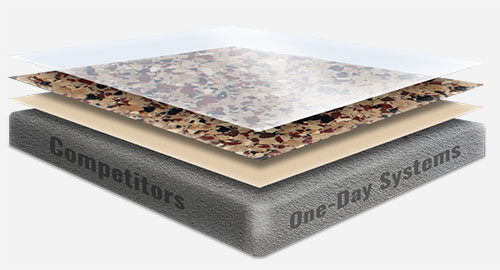

Theirs

1-Day Coating System = ~20 mils thick

1. Our full-flake garage floor coatings use 100%-solids liquid coatings only (100% Solids MME as the epoxy primer and 100% Solids Poly Hybrid Gen II, a polyaspartic, as the clear topcoat). This is not the case for 1-day systems which use lower solids products.

2. We apply a thick, moisture-mitigating epoxy primer coat direct-to-concrete (never a wafer-thin polyurea) because epoxies penetrate concrete better than polyureas. Because of this, epoxies can resist concrete moisture vapor and high hydrostatic pressures…so the likelihood of peeling is far less. Our warranty is indicative of this. Also, our thick primer coat is equivalent to a primer and color coat combined. The thickness also helps resist hydrostatic pressures.

Note: Moisture-mitigating epoxies are excellent primers, but lousy top coats because they can chalk when exposed to UV. Conversely, polyurea-polyaspartics are excellent UV and chemical-resistant top coats but lousy primers, especially on concrete with medium to high moisture content. We use the best properties of both epoxies and polyurea-polyaspartics to produce our coating systems!

3. We offer conventional thermoplastic full-flake flooring, but also offer mica stone-infused blends(with over 30 choices). No 1-day installer offers these options.

4. Because the flakes get fully embedded in the thick primer coat, we can buff the flakes mechanically(Day 2). Because a 1-day polyurea primer is so thin, the chips aren’t properly embedded and can’t be buffed…they have to be lightly and manually scraped with a scraper.

5. We top our full-flake garage floor coatings with 2 polyaspartic clear top coats (not just 1 like the 1-day systems).

6. Our full-flake floors are therefore 4 layers thick (5 if you include the primer as a double coat)…over 35 mils thick compared to the <20 mils for 1-day coating.

7. Because our floors use a moisture-mitigating epoxy as primer and dual (quality) polyaspartic topcoats, we offer a REAL GUARANTEE for moisture-related issues and hot-tire transfer (that is, we have no hidden warranty exclusions for moisture like 1-day systems).

8. We install our coating systems in 2 days…not 1. This is a good thing. It’s necessary when applying quality flooring!

9. This all begs the question:

“If ‘1-day’ contractors are so confident in their polyurea-polyaspartic coatings, WHY WON’T THEY WARRANT MOISTURE AND STAINING?“, given that these are the 2 most common causes of concrete coating failures!

10. Here are real examples of “1-day” warranty exclusions:

1-Day Installer (Example 1): “…excluded from the floor coating warranty…peeling or delamination caused by moisture underneath the slab on which the floor coating was installed. Contractor will test for such moisture and suppress it where needed but cannot warranty that such moisture will not cause peeling or delamination”…and “staining from tires – plasticizers used in the tire industry to provide more traction can leach out of the tire. While polyaspartic coatings resist tire staining better than other coatings, we cannot prevent this from occurring.

1-Day Installer (Example 2): “…does not guarantee against…moisture intrusion, hydrostatic pressure or other moisture-related issues are not included in our warranty”. To avoid tire staining or tire marks on your floor, vehicle pads are recommended for motorcycles, all-terrain vehicles, high-performance vehicles, and vehicles that are not moved regularly.